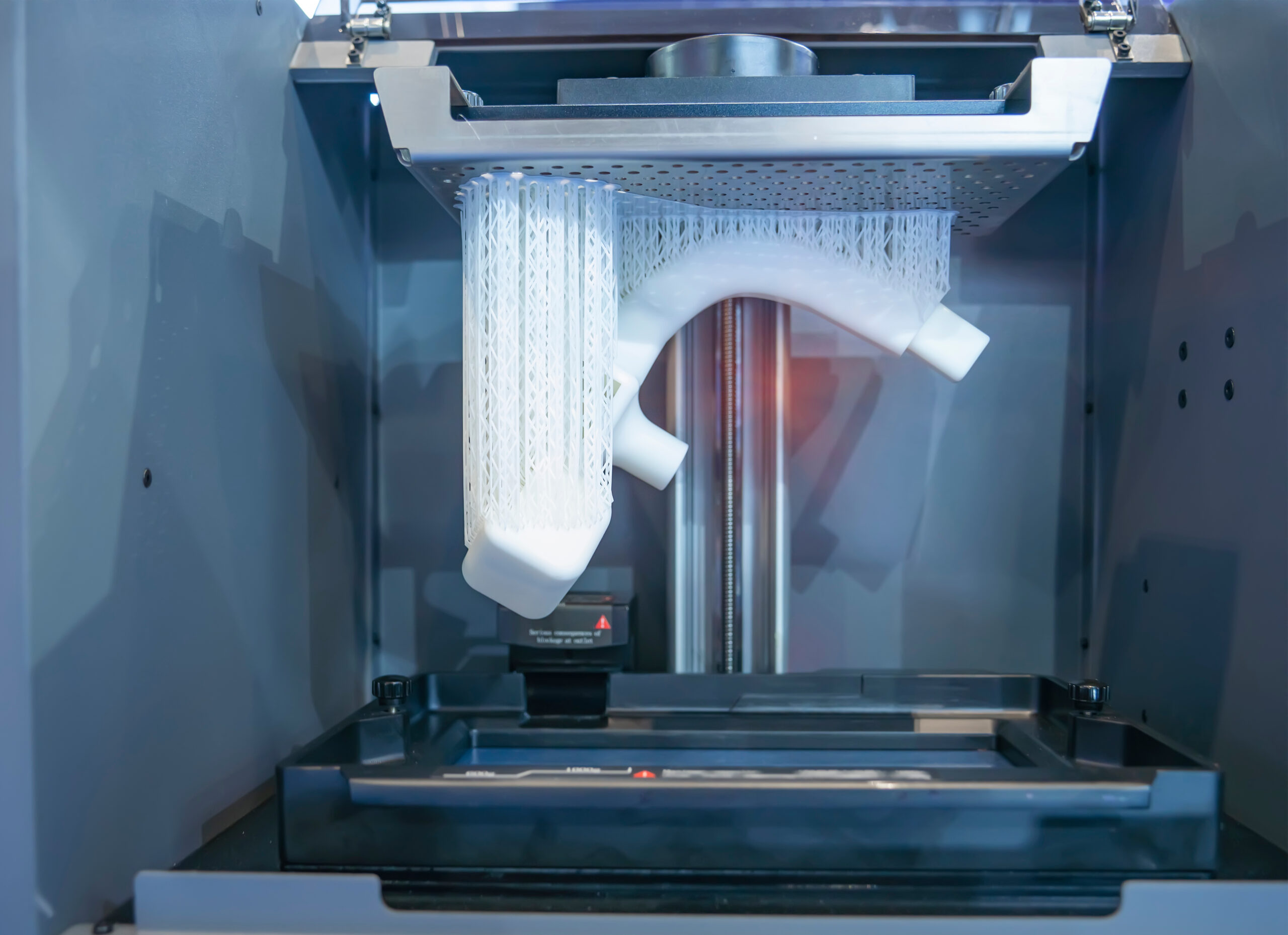

SLA (STEREOLITHOGRAPHY)

Stereolithography is an excellent process to produce extremely accurate physical models of 3D CAD data. Using replicate materials of PP, ABS and clear PC, build layers (as small as 0.05mm) can produce fine details on parts on a single build envelope of 350mm x 350mm x 400mm. The post-processing of the SLA models can include painting (gloss, textured and light spark finishes) which can transform the models into soft tooling masters, display/concept models and finished components.

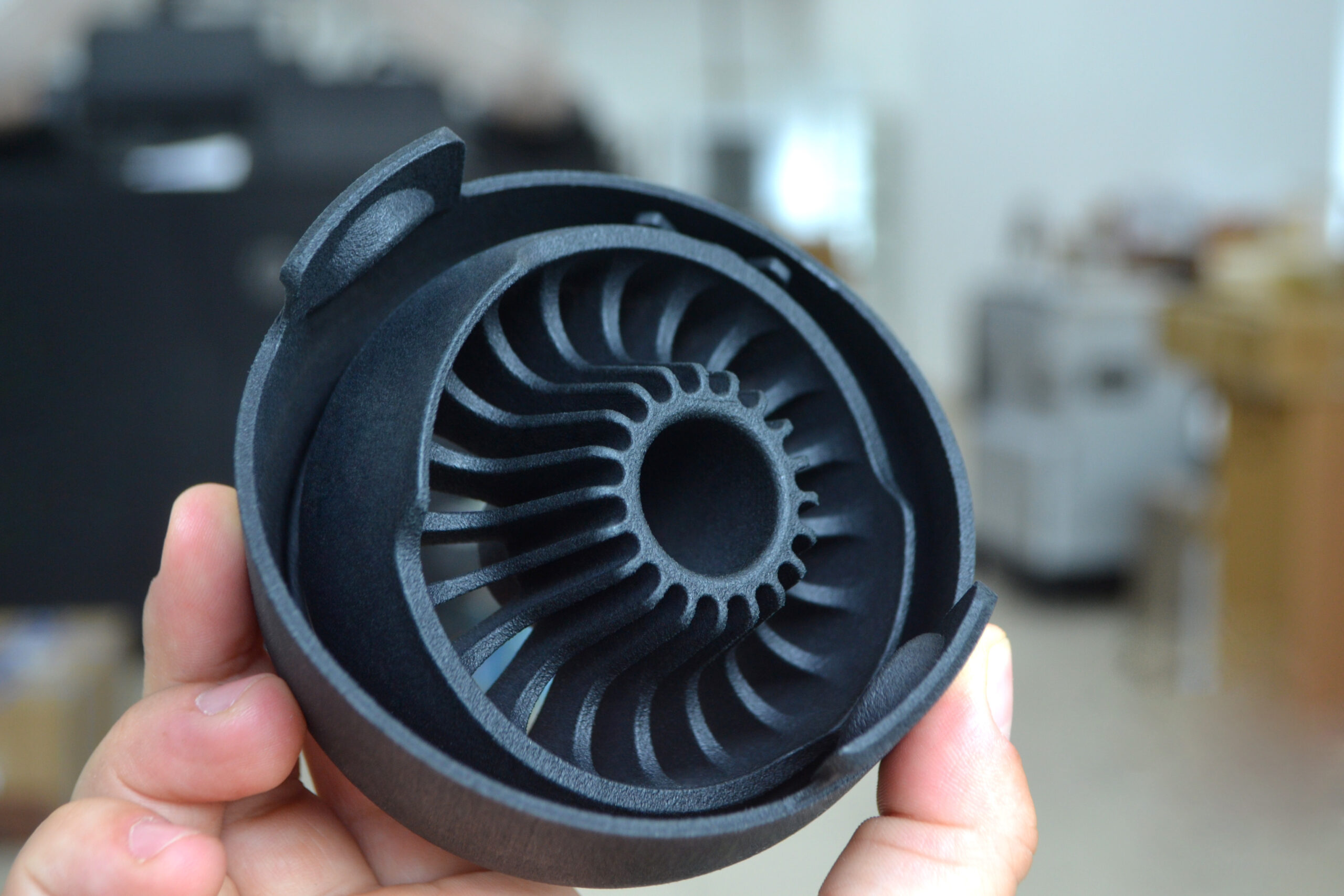

SLS (SELECTIVE LASER SINTERING)

This additive manufacturing layered process, using nylon and glass-filled nylon powders to produce functional and robust prototype components, is a cost-effective, accurate and rapid way to prove concepts and create low volume toolless usable components. The maximum single build envelope is 400mm x 280mm x 330mm. Alternatively, significantly larger parts can be produced by assembling multiple sections of components.

DLS (DIGITAL LIGHT SYNTHESIS)

This process differs from the conventional layer by layer build approach to additive

manufacturing, and instead applies a continuous liquid interface which is cured by

digital light synthesis. This allows for continuously cured parts with enhanced build quality

and strength. A buildsize of 18,9 x 11,8 x 32,6 cm 3 allows for textured and smooth finishes in

a variety of rigid and flexible resin grades. At ID Mouldings, we see this revolutionary process

as an alternative to moulding smaller parts in volume. The DLS process is a rapid and

cost-effective alternative to conventional manufacturing techniques.

MJF (MULTI JET FUSION)

Multi Jet Fusion is a powder bed technology much like SLS however it uses a superior technique while combining the printing powders, therefore is it significantly faster and it produces a much better surface quality of part compared to SLS. Different grades can be used, with one of the most common being PA12. ‘Advantages of this process include speed (x10 faster than other powder based additive manufacturing), surface quality and a wide variety of grades to select from.