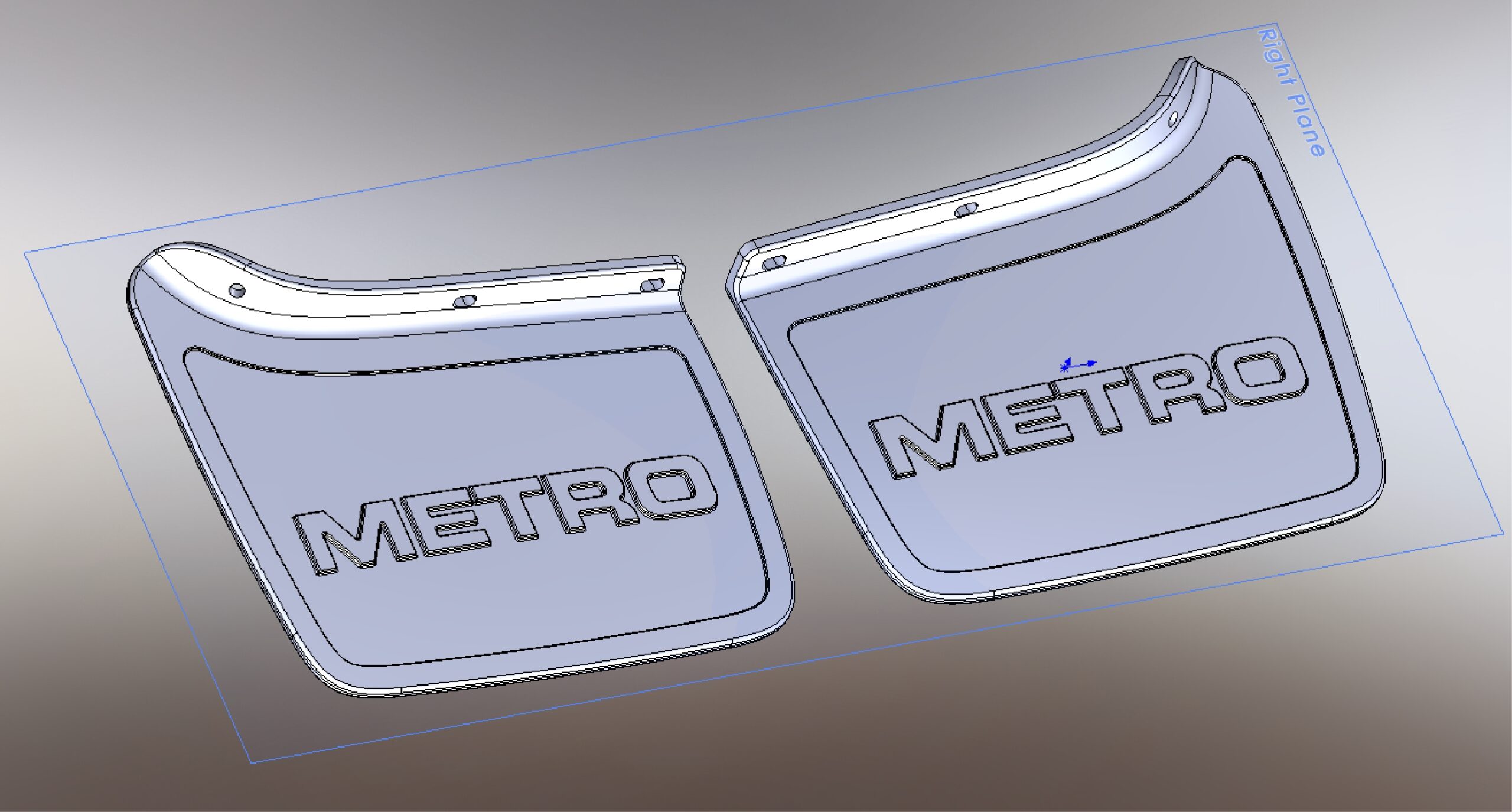

Whether a customer has an idea or a sketch, we can bring their concept to life. Using 3D Computer Aided Design (CAD) we can model the idea/design and create usable 3D files that we can then use to create product prototypes and develop further into a production manufacturing process.

This is generally where we take an existing product and copy it or amend the design of the product for a production use. For example, an obsolete classic car part that has been damaged could be copied and replaced or a machine could have a part replaced or amended. Typically, we would create a 3D CAD model from scratch or have a part 3D scanned to which we can then use to take into manufacturing.

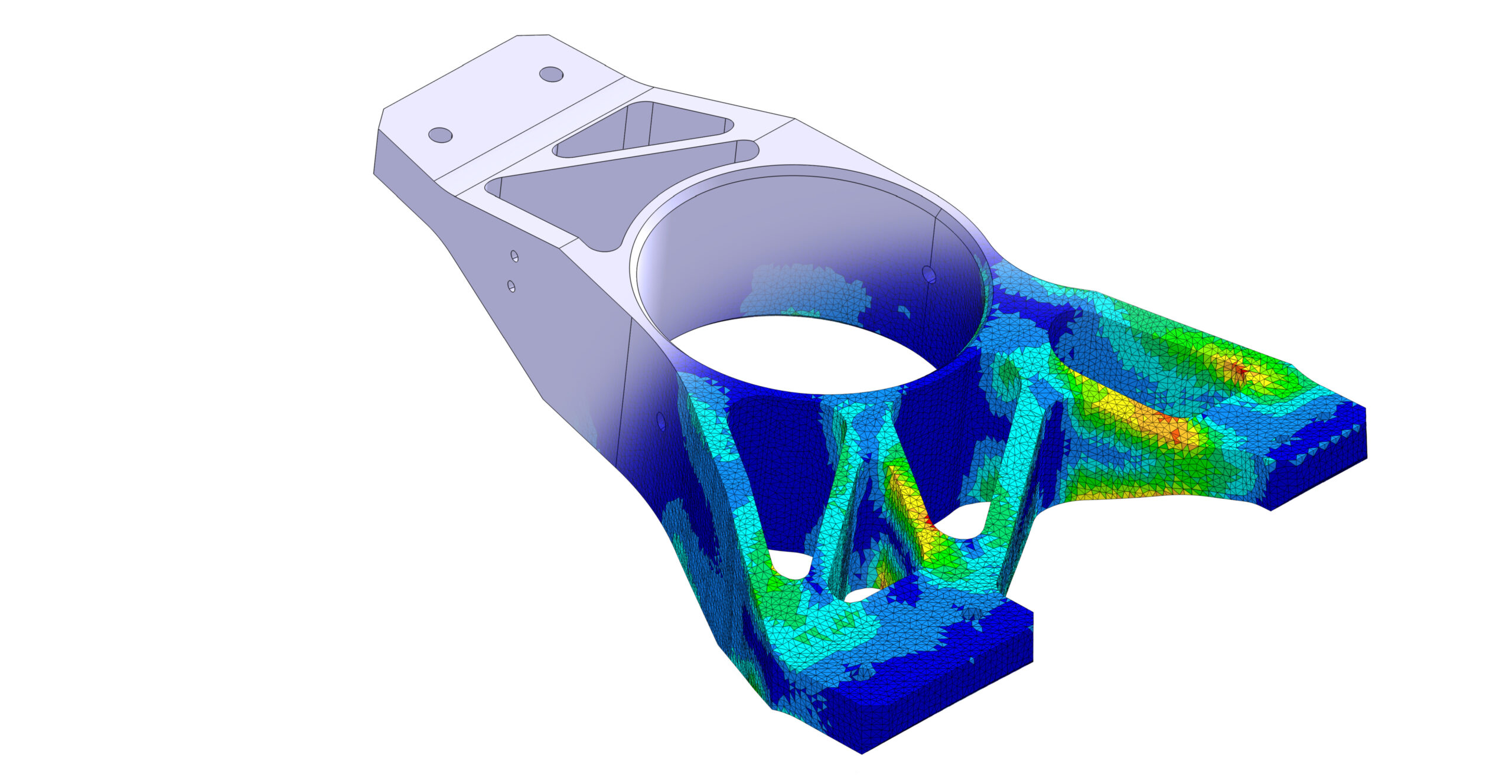

CAD simulation can be used to test and gauge the functionality or success of a product in use or the viability of manufacturing a product, by running simulation on 3D CAD software. Tests such as mould-flow analysis (how well moulded material will enter and fill a mould cavity) can be carried out.

CAD Model Rendering is used to visualise what a final product may look like once manufactured. Our CAD software can produce a photo realistic image of a CAD model. This can often be used for styling purpose and choosing colour variations for a product as well as creating artwork for presentations without the need to have a physical product.

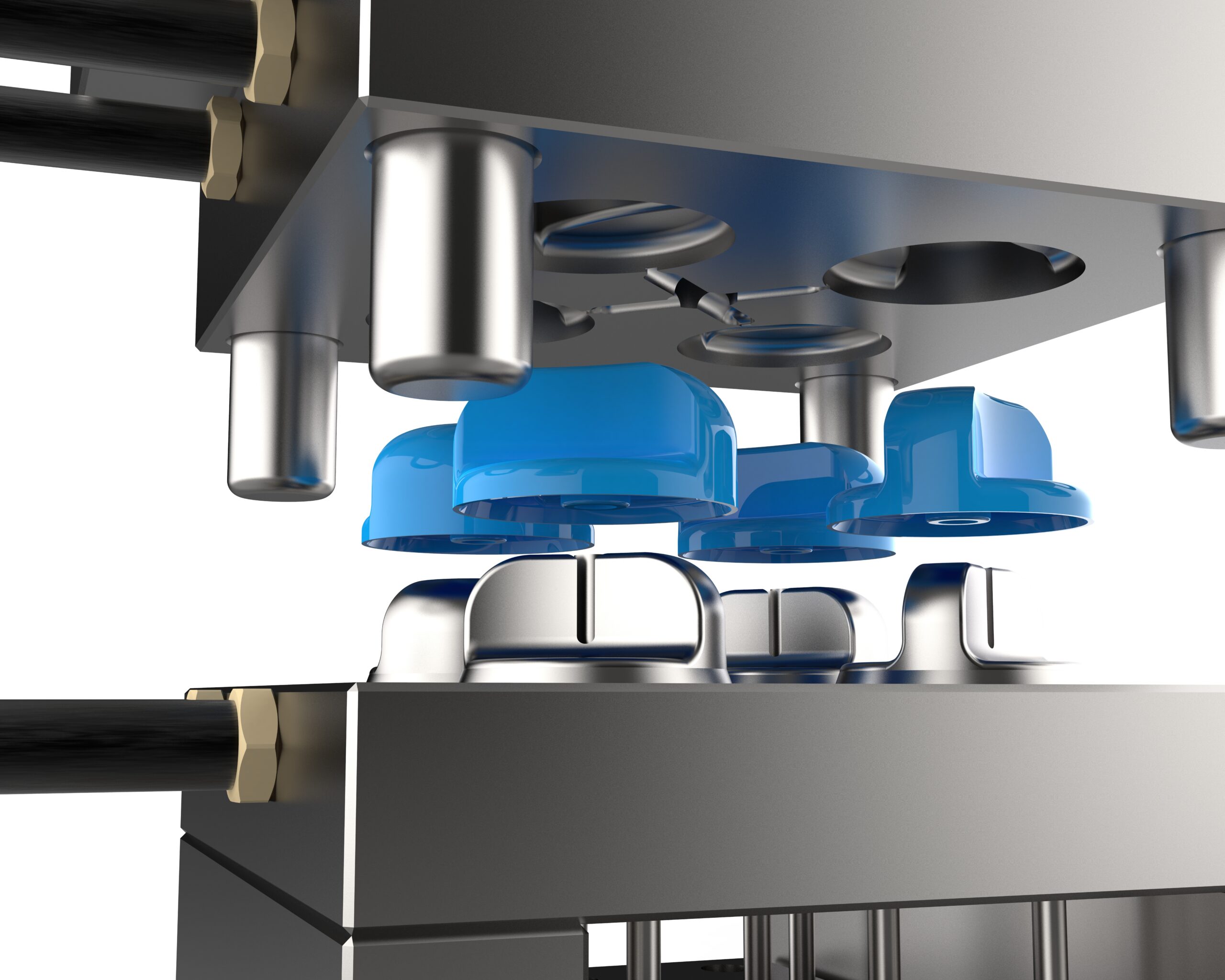

We have over 20 years combined experience in designing tooling for a variety of moulding applications. We will liaise with our clients to advise them on any design changes of a component before going in to tooling design. Typically steel or aluminium tooling is used for high volume production and model board and GRP are used for prototype and lower volume moulding processes.

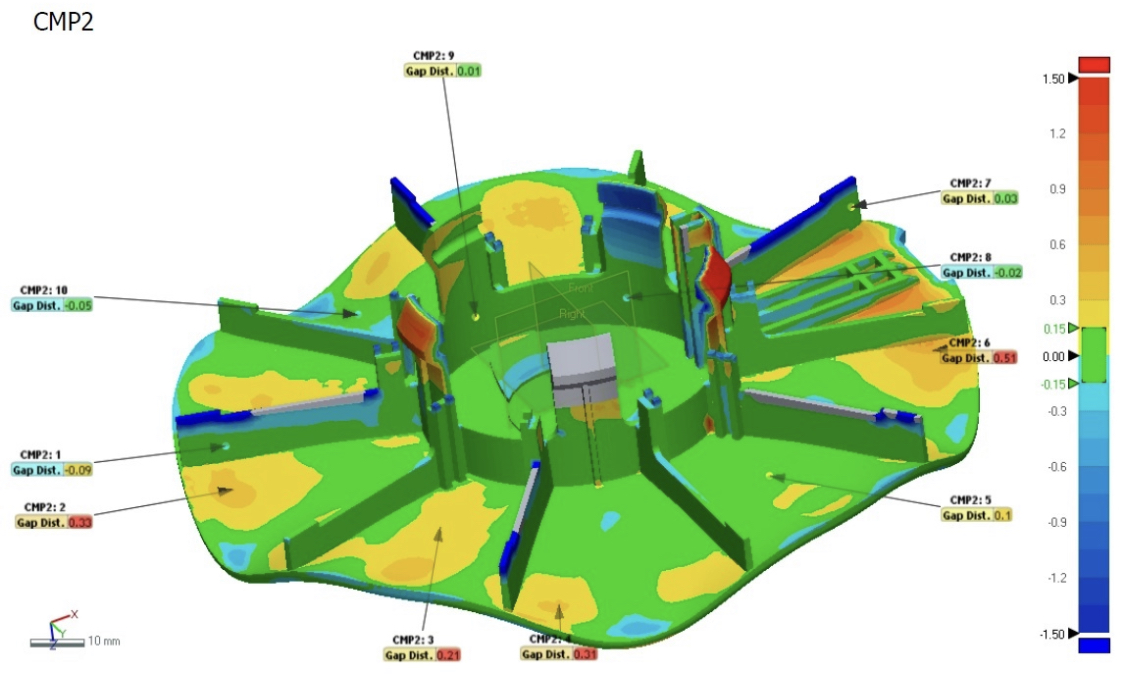

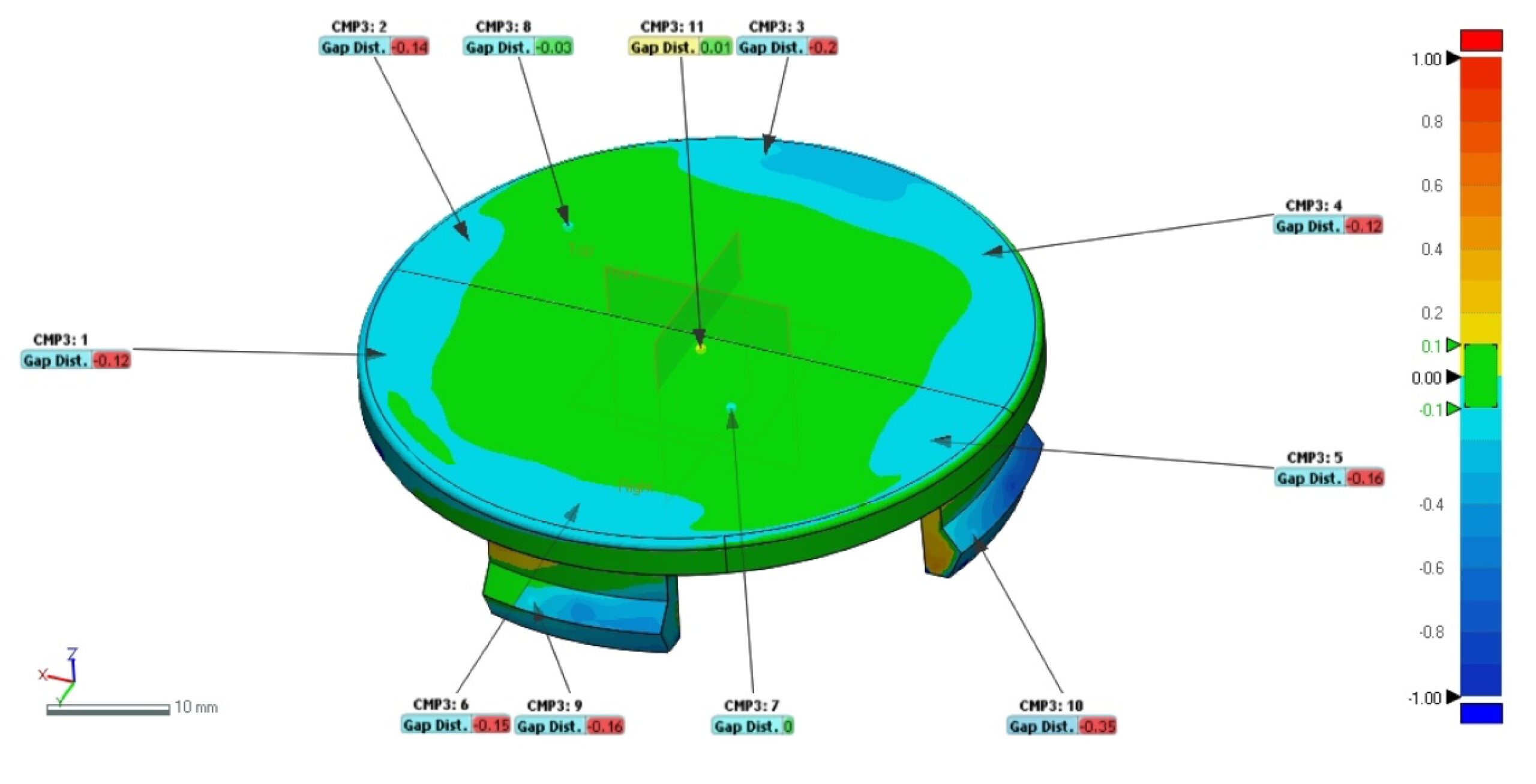

3D scanning is an integral part of our manufacturing process, whether used to reverse engineer an old part so we are able to remanufacture it or to validate a newly developed part and check the dimensional tolerances. There are a variety of scanning options including Laser Triangulation, White Light or Contact Based probe inspection amongst others.

Dimensional reports can be carried out if required. The process involves one or more physical parts being 3D scanned (often in a holding jig) and reviewed against the original 3D CAD. This process validates the parts as appropriate to use or shows up any abnormalities and issue prior to the parts being assembled or going into production.

+44 (0)121 779 4762

One of our experts can call you back to discuss any queries you may have.

ID Mouldings Limited. Registered in England Company No. 11783077

Website Zubru Creative