ID Mouldings has the expertise and knowledge within the manufacturing industry to be able to advise on the best route to production for prototype projects, low volume projects and larger volume production.

Whether it be a visual concept model, a working test prototype or production intent components, we will direct our clients in the right direction depending on the intended application and requirements.

ID Mouldings strongly supports and are passionate about British manufacturing; we will not compromise on quality for cost when nominating the route to production. Our colleagues include additive manufacturing, CNC machining, injection moulding, prototyping, metal fabrication and finishing/painting experts.

Why do we use a prototype

Prototypes are an important part of product development process. Prototypes are generally an initial version of a product of which the developers/designers will scrutinise and learn from. It can take many revisions of a prototype until the final product has been released for manufacture.

Prototypes can come if lots of forms including:

- Basic sketch models, where an initial physical product comes together, this could be shaped polystyrene, carboard, clay and anything that could be used represent the physical body or feature of a product.

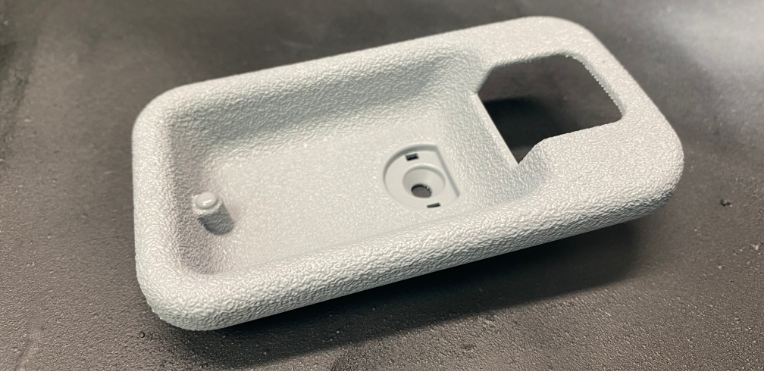

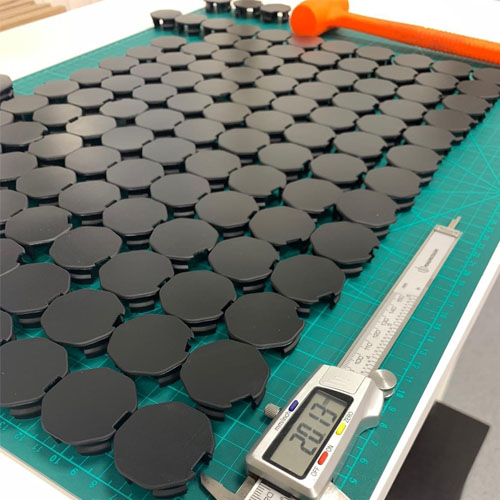

- Models/Working Models, are a step up from a basic model are generally more refined often with usable features of the final product. Additive manufacturing (3D Printing including SLA, SLS, FDM and DLS) is a common way to achieve the desired outcome. Vacuum casting and CNC machining are also commonly used for this level of product development and prototyping.

- Final Prototypes and Pre-production is a stage where generally very little will be changed about the physical look of the product. This stage can often use some or early production tooling. Development may be carried out at this stage with design for manufacture in mind (a design can be changed to help the manufacturing process). The manufacturing process at this stage could include Reaction Injection Moulding (RIM) or Injection Moulding.

Prototype examples

FAQS

Prototypes are created to give the designers/engineers a physical understanding of their product. This could consist of a basic visual model or a fully working and usable product.

Prototyping can be costly, depending how many versions of the prototype are made and what manufacturing process are used. The prototyping process can however save a lot of time and money ironing out any problem before production tooling is invested in.