EXPERT PROTOTYPING SUPPORT & RAPID PRODUCT DEVELOPMENT CONSULTANCY

At ID Mouldings, we help businesses manage prototype projects from the initial concept through to production, making sure every stage of the product development process is efficient, accurate, and aligned with your goals. Whether you need a visual concept model, a working test prototype, or production-intent components, we guide you towards the most suitable manufacturing route based on your specific application and requirements.

With extensive expertise in additive manufacturing, CNC machining, injection moulding, metal fabrication, and finishing, we support startups, engineers, and manufacturers in turning ideas into reality quickly and cost effectively. We are passionate about British manufacturing and are committed to maintaining high standards of quality across both low-volume and full-scale production.

As part of our prototype consultancy service, our team provides expert advice and connections to help you choose the right manufacturing partners, materials, and processes for your project.

What is Prototype Sourcing & Why Does It Matter?

Prototype sourcing involves selecting the most suitable materials, technologies, and manufacturing partners to produce early-stage versions of your product. These prototypes are essential for testing usability, validating performance, and uncovering design flaws before committing to full-scale manufacturing.

For complex industries like automotive, medical, or aerospace, choosing the right development path can mean the difference between a smooth launch and costly delays. That’s where ID Mouldings’ consultancy makes a real difference—we de-risk your development by guiding every technical decision through a manufacturing lens.

Our Consultancy Covers

As part of our prototype consultancy service, our team provides expert advice and connections to help you choose the right manufacturing partners, materials, and processes for your project.

- Design for Manufacture (DFM) advice to optimise your product for production.

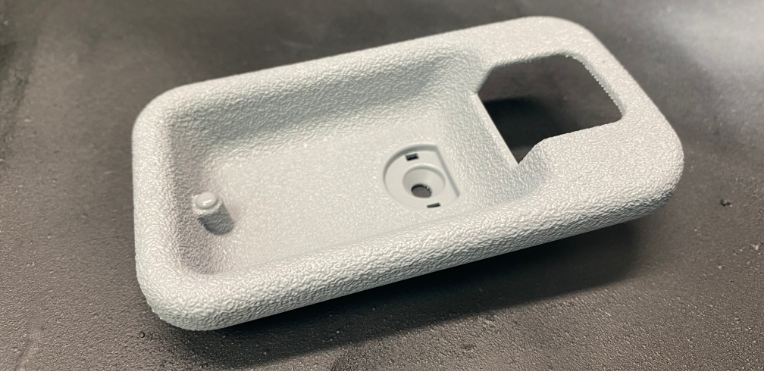

- Material and process selection including PU Moulding, S-RIM, CNC machining, and 3D printing.

- Access to rapid tooling solutions and low-volume moulding options.

- Supplier evaluation, sourcing and technical vetting to ensure the right manufacturing match.

- Prototype testing strategies, feasibility assessments, and scale-up preparation.

Not sure where to start, ask an expert

Who is this service for?

As a prototyping company, we’ve supported a wide range of clients, from idea-stage inventors to major brands, helping them avoid common prototype pitfalls and launch with confidence.

Start Ups

Ideal for early-stage businesses turning concepts into testable products without overextending budget or timelines.

Medical Product Developers

Get clinically relevant prototypes quickly, with careful attention to compliance and testing demands.

Automotive & Motorsport Engineers

Support for custom car parts, performance testing, and iterative adjustments in fast-moving sectors.

Aerospace Teams

Precision prototyping for components with demanding shapes, tolerances, and performance requirements.

Body kit Manufacturers

Perfect for evaluating new designs and textures before committing to full production tooling.

What Makes ID Mouldings Different?

We don’t just source we advise. With decades of hands-on experience in tooling and plastic manufacturing, we understand the intricacies that come with selecting the right development pathway. Our consultancy is rooted in practical engineering knowledge, meaning we can help you avoid costly missteps and instead focus on what will work best for your specific application. Whether you need input on design tolerances, material suitability, or scaling considerations, we provide detailed, context-aware advice that adds real value.

We handle complexity. From PU-RIM to high-precision injection moulding, we’ve worked across sectors where detail, consistency, and performance are critical.

Affordable prototype sourcing without compromising quality

Designed for real-world testing and production readiness

UK-based team, familiar with compliance standards and reshoring support

Access to decades of technical manufacturing experience

Scalable from prototype to low-volume production

Not sure where to start, ask an expert

From Sourcing to Testing: A Full Prototype Lifecycle

Understand your goals, design intent, and end-use requirements to establish the right technical starting point.

Consultation & Brief

Feasibility & Process Planning

We recommend the most appropriate method: PU moulding, SLS, CNC machining, or vacuum casting based on scope, cost, and function.

Sourcing the Right Partner or Process

We connect you with vetted suppliers or use in-house resources to deliver the ideal production route.

Prototype Manufacture & Delivery

Receive functional, test-ready parts that reflect true production quality, finish, and tolerances.

Testing, Measurement & Review

We help validate performance, verify tolerances, and refine your design before tooling or full-scale manufacture.

FAQS

Prototypes are created to give the designers/engineers a physical understanding of their product. This could consist of a basic visual model or a fully working and usable product.

Prototyping can be costly, depending how many versions of the prototype are made and what manufacturing process are used. The prototyping process can however save a lot of time and money ironing out any problem before production tooling is invested in.

Bringing Manufacturing to the UK

At ID Mouldings, we support businesses looking to bring manufacturing back home. Reshoring improves quality control, shortens lead times, and supports the local economy. Whether you’re refurbishing tools or switching to UK-based production, we make the transition seamless.

Faster Delivery & Reduced Lead Times